Products Knowledge

Fruit Juice OEM Manufacturing Process: Step-by-Step Guide

As the global demand for healthy, convenient, and flavorful beverages continues to rise, many brands are turning to Fruit Juice OEM manufacturing to bring their products to market efficiently. OEM partners provide the expertise, facilities, and production systems needed to transform fresh fruits into high-quality, shelf-ready juice products. Instead of investing in costly factories and technical teams, brands can focus on marketing, branding, and distribution while leaving production to specialists.

However, to make informed decisions and ensure product success, it is essential to understand how the Fruit Juice OEM manufacturing process works. From sourcing raw materials and developing formulations to filling, packaging, and quality control, every step plays a crucial role in delivering consistent, safe, and appealing beverages. This guide explains the Fruit Juice OEM manufacturing process step by step, helping beverage brands gain clarity, reduce risks, and build a strong foundation for long-term growth.

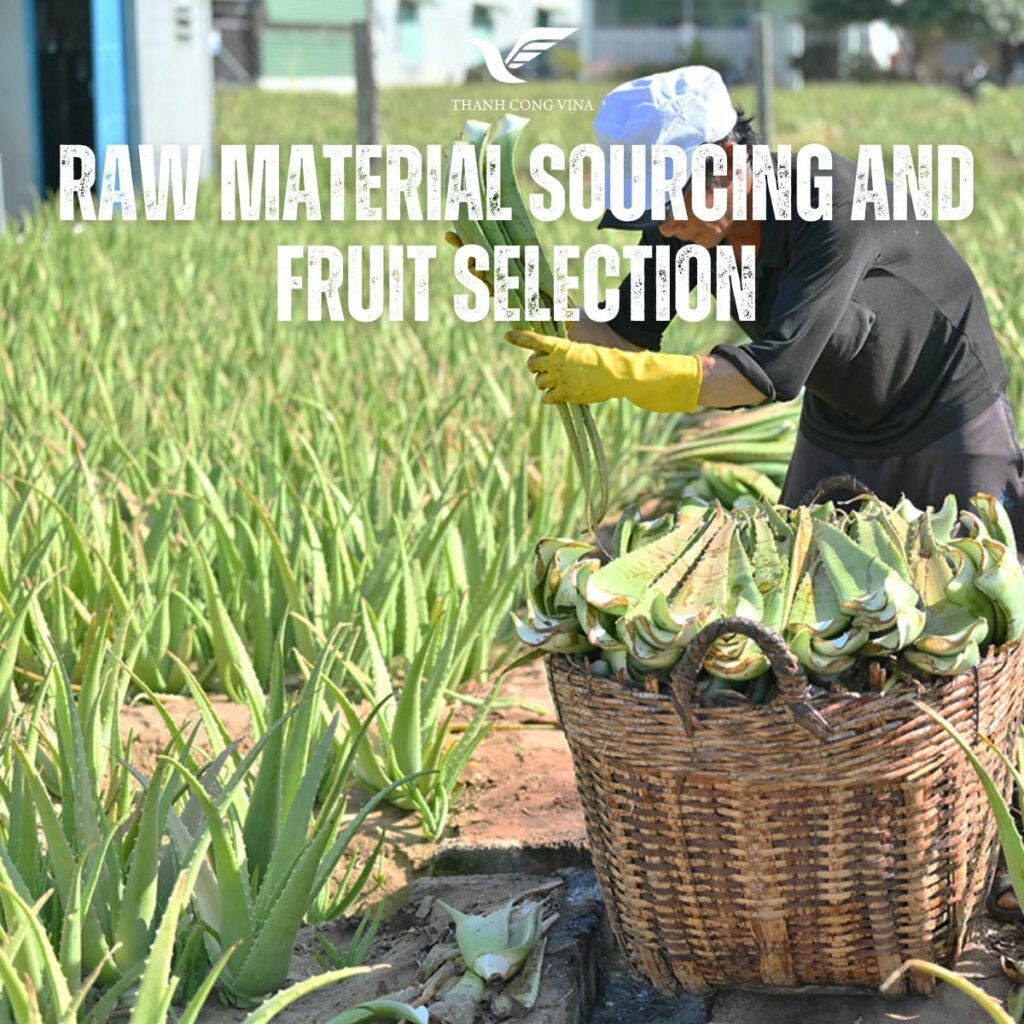

1. Raw Material Sourcing and Fruit Selection

Choosing High-Quality Fruits

The foundation of every successful fruit juice product is the quality of its raw ingredients. Fruit Juice OEM manufacturers work with certified farms and trusted suppliers to source fresh, ripe fruits that meet strict safety and quality standards. The choice of fruit directly impacts flavor, color, nutritional value, and overall product appeal.

OEM partners evaluate factors such as sugar content (Brix level), acidity, ripeness, and aroma before approving any batch of fruit for processing. This ensures consistent taste and performance across all production runs.

Traceability and Safety Assurance

Reliable Fruit Juice OEM facilities maintain full traceability for their raw materials. Each fruit batch is documented from farm to factory, reducing risks related to contamination, pesticide residue, or supply chain disruptions. This traceability is especially important for export markets where regulatory compliance is strictly enforced.

2. Fruit Processing and Juice Extraction

Cleaning, Sorting, and Preparation

Once the fruits arrive at the factory, they undergo thorough cleaning to remove dirt, pesticides, and surface contaminants. Advanced washing systems and visual inspections ensure that only high-quality fruits proceed to the next stage.

After cleaning, fruits are sorted by size and quality, then peeled, sliced, or crushed depending on the type of juice being produced.

Juice Extraction Techniques

Different fruits require different extraction methods. Citrus fruits are often pressed, while tropical fruits like mango or pineapple may be pulped and filtered. Fruit Juice OEM manufacturers use modern extraction equipment to maximize juice yield while preserving natural flavor and nutrients.

The extracted juice is then filtered to remove seeds, fibers, or unwanted solids, resulting in a smooth, consistent liquid base.

3. Formulation and Flavor Development – Fruit Juice OEM

Custom Recipe Creation

One of the biggest advantages of working with a Fruit Juice OEM partner is access to professional formulation expertise. Based on the brand’s target market and product positioning, OEM food technologists develop customized recipes that balance sweetness, acidity, and mouthfeel.

This may include blending multiple fruit juices, adjusting sugar levels, or adding natural flavors to enhance taste.

Functional and Nutritional Enhancements

Many brands want to add value to their products by including vitamins, minerals, or functional ingredients such as collagen or dietary fiber. Fruit Juice OEM manufacturers carefully test these additions to ensure stability, safety, and compatibility with the juice base.

4. Quality Testing and Safety Control

Microbiological and Chemical Testing

Before large-scale production begins, the juice formulation undergoes strict laboratory testing. This includes microbiological analysis to detect harmful bacteria and chemical tests to verify pH levels, sugar content, and ingredient stability.

These tests ensure that the product meets both internal quality standards and international food safety regulations.

Consistency Across Batches

Fruit Juice OEM facilities implement standardized quality control systems to maintain consistency from batch to batch. This is critical for brand reliability, especially for products distributed across multiple regions.

5. Pasteurization and Shelf-Life Optimization

Ensuring Product Safety

Pasteurization is a key step in the Fruit Juice OEM manufacturing process. By applying controlled heat treatment, harmful microorganisms are eliminated while preserving flavor and nutrients.

Different methods, such as hot-fill or aseptic processing, are used depending on the product type and packaging format.

Extending Shelf Life

Proper pasteurization, combined with airtight packaging, helps extend shelf life without the need for artificial preservatives. OEM manufacturers conduct shelf-life testing to determine how long the juice maintains quality under various storage conditions.

6. Filling and Packaging

Automated Filling Systems

Once the juice is processed and pasteurized, it is transferred to automated filling lines. These systems ensure accurate volume control, hygiene, and efficiency.

Fruit Juice OEM manufacturers use specialized equipment for bottles, cans, pouches, or cartons, depending on the brand’s packaging choice.

Branding and Labeling

Labels play a vital role in product identity and compliance. OEM partners ensure that all packaging includes correct nutritional information, ingredient lists, barcodes, and regulatory markings required for each target market.

7. Final Quality Inspection and Storage

Visual and Functional Checks

Before products leave the factory, they undergo final inspections for seal integrity, label accuracy, and overall appearance. Any defective units are removed to protect brand reputation.

Warehouse and Distribution Readiness

Finished products are stored in controlled environments to maintain quality until shipment. Fruit Juice OEM suppliers also assist with export packaging and logistics preparation for international markets.

8. Scalability and Continuous Improvement

Scaling Production for Growth

As brands grow, production volumes increase. Fruit Juice OEM manufacturers adjust batch sizes, sourcing strategies, and logistics to support expansion without compromising quality.

Ongoing Product Optimization

Consumer preferences change over time. OEM partners continuously refine formulations, packaging, and processes to keep products competitive and aligned with market trends.

Conclusion

The Fruit Juice OEM manufacturing process is a structured, science-driven system designed to deliver safe, consistent, and high-quality beverages at scale. From sourcing premium fruits and developing customized formulations to ensuring strict quality control and efficient packaging, every step plays a critical role in product success. By understanding this process, beverage brands can make smarter decisions, reduce risks, and accelerate their time to market.

Thanh Cong Vina is a trusted Fruit Juice OEM partner known for its advanced production capabilities, certified quality systems, and strong export experience. With a commitment to innovation, safety, and consistency, Thanh Cong Vina supports brands at every stage of the manufacturing journey. Choosing Thanh Cong Vina as your Fruit Juice OEM partner means gaining a reliable foundation for sustainable growth in the global beverage industry.